Material structure:

Inconel is a precipitation-hardenable nickel-chromium alloy containing significant amounts of iron, niobium, and molybdenum along with lesser amounts of aluminum and titanium. (Matweb.com, 2017) For this study we will be mainly focusing on Inconel 718 wich consists of the following composition:

| Ni | Fe | Cr | Nb | Ti | Al | Mo | C | Co | |

| Specification | 50.0–55.0 | Balance | 17.0–21.0 | 4.75–5.50 | 0.75–1.15 | 0.20–0.80 | 2.80–3.30 | <0.08 | — |

Table 1: Specification (wt.%) of alloy 718 (Dehmas et al., 2017)

Nickel, chromium, iron and other elements offer strong corrosion resistance at a temperature above 950 °C. Nickel prevents chloride-induced stress corrosion, cracking, attack of organic and inorganic compounds and more. Chromium offers an ability to prevent corrosion in oxidizing media and Sulphur compounds. Molybdenum resists pitting attack ( a localized form of corrosion by which cavities or “holes” are produced in the material). (Heanjia Super Metals Co. Ltd., 2017)

Microstructure:

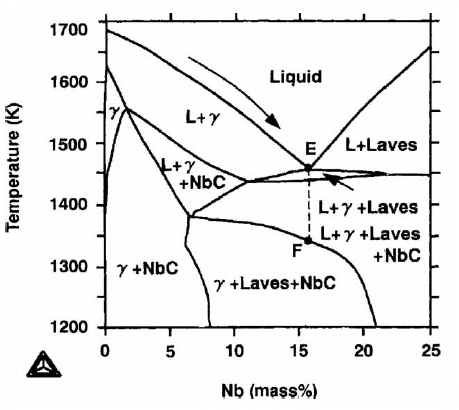

The strength of alloy 718 comes from coherent solid-state precipitates, which is for a small part γ’-Ni3Al but mostly γ’’-Ni3Nb precipitates. Both of these precipitates are ordered forms of the FCC-A1 Ni-rich matrix (L12 in the case of γ’ and DO22 in the case of γ”). The solvus of these precipitates is at about 900–920°C. γ’’ precipitates are metastable while the stable form of Ni3Nb is the so-called delta phase which is orthorhombic (a system of crystallization characterized by three unequal axes at right angles to each other).

Forging of the alloy 718 is done at about 980°C slightly below the solvus of the delta phase, in such a way that this phase is sufficiently abundant to be effective in limiting grain growth but not too abundant to avoid significant Nb depletion in the matrix which would affect the subsequent strengthening by γ’ precipitation. This latter precipitation is generally obtained after two successive periods of isothermal aging at 750°C and 650°C, respectively. (Dehmas et al., 2017)